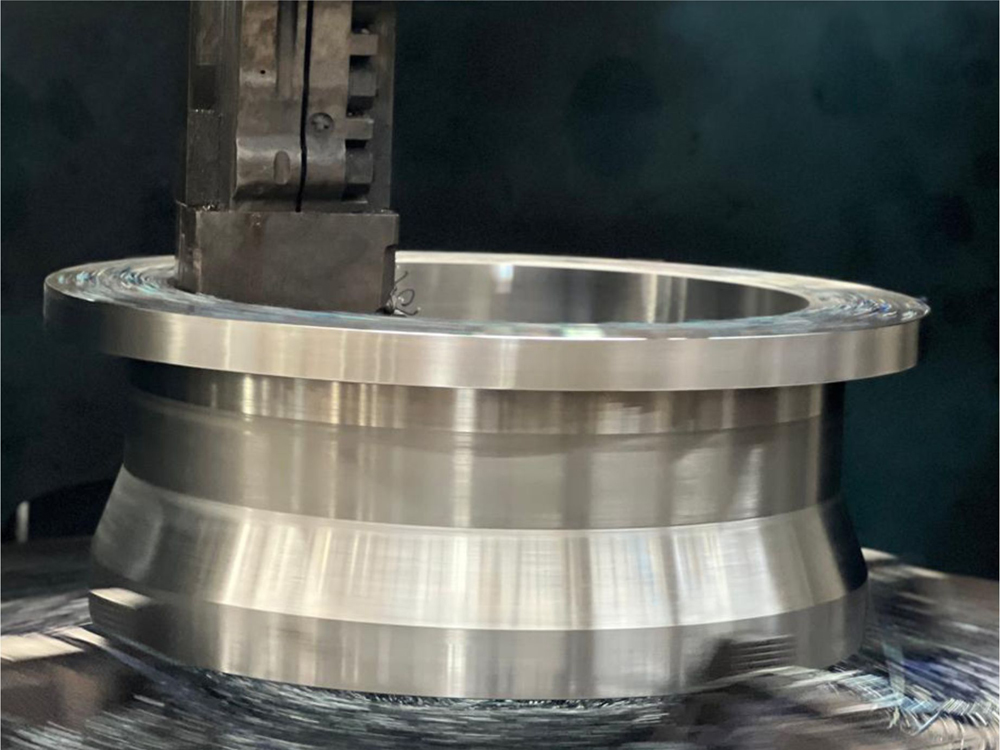

High-Precision Machining for Forged Components

At Shailesh Forging Works, our state-of-the-art machining facility is equipped with a diverse fleet of CNC and VTL machines, enabling high-precision machining of seamless rings and forged components up to 3000 mm in diameter.

With a skilled team of machinists and world-class infrastructure, we deliver components that meet stringent drawing tolerances, surface finish requirements, and dimensional accuracy. From complex geometries to large-scale production, our machining setup ensures repeatable performance and flawless quality.

Machinery Overview

Our machining shop includes a combination of conventional and CNC-controlled equipment to handle varying complexities of forged parts:

Radial Drilling Machines – 2 Nos

For accurate drilling and hole-making operations in large forged sections.

CNC VTL (Vertical Turning Lathe) Machines – 4 Nos.

Used for turning large diameter forged rings and components with micron-level precision.

CNC Machines – 4 Nos

For milling, facing, and turning operations on custom geometries and critical surfaces.

VTL Machines – 15 Nos

Ideal for high-capacity machining of large forged rings, flanges, and hubs.

Machining Capabilities

Maximum machining diameter: 3000 mm

Tolerance

As per customer drawings or ISO standards

Finish

Machined, semi-machined, or final-finished

Materials

Carbon steel, alloy steel, stainless steel, and special forgings Custom tooling and fixturing support available

Quality Focus at Every Stage

Our machining department is integrated with real-time quality control, supported by digital measurement instruments, 3D gauges, and in-process inspection. Every machined part undergoes:

Dimensional accuracy verification

Surface finish and roughness inspection

Hardness testing (as required)

Visual and defect analysis

Serving Multiple Industries

Our precision machining services are trusted by OEMs and manufacturers in:

Wind Turbines

Gearbox & Transmission

Oil & Gas

Marine

Energy & Power