Up Setting Forging – Precision Open Die Forging for Custom Heavy Components

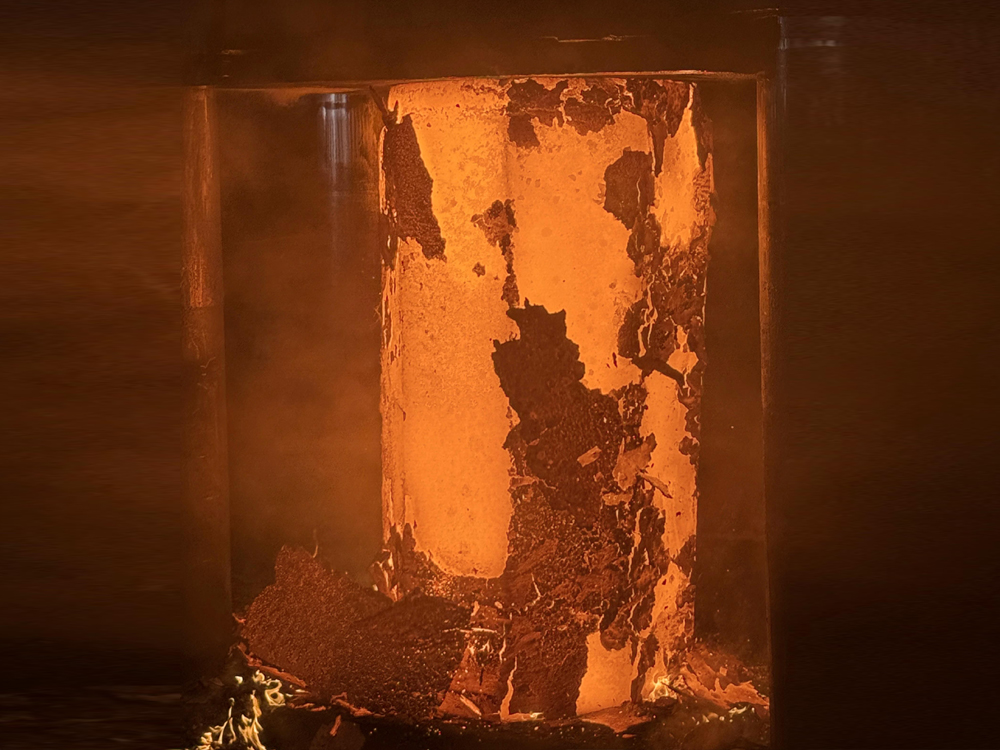

At Shailesh Forging Works, our open die forging facility is engineered to manufacture high-integrity, heavy-duty forged components with superior strength and metallurgical properties. Using state-of-the-art forging presses and drop belt hammers, we shape heated steel billets into precise forms, ensuring optimal grain structure and mechanical performance.

Whether for a single custom job or batch production, our forging experts ensure each component meets rigorous standards and exacting tolerances.

What is Open Die Forging?

Open die forging is a process where a hot metal workpiece is compressed between flat or contoured dies without completely enclosing it. This technique allows for:

- Excellent metal flow

- Superior structural integrity

- Customization for large, unique shapes

- Reduction of porosity and voids

- Enhanced grain alignment for critical applications

Our Up Setting Forging Capabilities

We specialize in the production of forged components for industries requiring durability, load resistance, and dimensional precision. Our facility can forge items in a wide range of sizes and weights:

- Weight Range: 50 kg to 4 MT

- Part Types: Shafts, discs, flanges, step shafts, gear blanks, sleeves, and custom shapes

- Material Types: Carbon steel, alloy steel, stainless steel, and special grades

Quality Assurance & Testing

Every forged product undergoes rigorous quality checks:

- Visual and dimensional inspection

- Ultrasonic and magnetic particle testing (if applicable)

- Material certification

- Surface and hardness testing

Our team is trained to ensure every product meets customer drawings and specifications.

Forging Equipment

To ensure versatile and high-capacity forging, our plant includes:

5 MT Drop Belt Hammer

Ideal for shaping large, high-strength parts with rapid deformation

900 MT Hydraulic Press

Mid-range press for consistent quality and precision

1200 MT Hydraulic Press

Suitable for medium-to-heavy forged products

2500 MT Hydraulic Press

For the heaviest jobs requiring extreme force and accuracy

Advantages of Our Forging Process

Exceptional strength & toughness

Uniform grain flow reduces stress concentrations

Low defect rates (cracks, porosity, shrinkage

Highly customizable for large and non-standard components

Compliance with international standards (ASTM, API, DIN, etc.)

Industries Served

Oil & Gas

Power Generation

Heavy Engineering

Mining

Shipbuilding

Renewable Energy